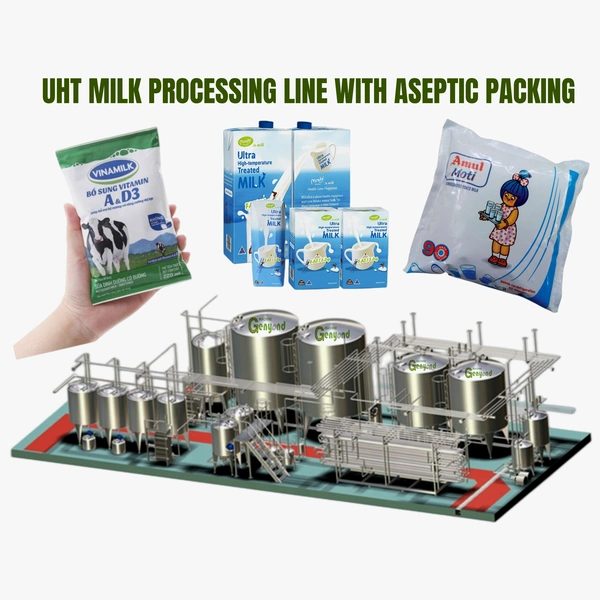

Complete UHT Milk Processing Line

With a product that can be stored for long periods without spoiling and with no need for refrigeration, there are many advantages for both the producer, the retailer and the consumer.

This includes expensive products such as milk, cream, desserts and sauces.

In a modern UHT milk production line (Ultra High Temperature) is pumped through a closed system. On the way it is preheated, highly heat treated, homogenized, ultra highly heat treated,

cooled and packed aseptically. Low acid (pH above 4.5 – for milk more than pH 6.5) liquid products are usually treated at 135 – 150C for a few seconds holding, by either indirect heating

or direct steam injection or infusion. High acid (pH below 4.5) products such as juice are normally heated at 90 – 95C for 15 – 30 seconds holding. All parts of the system downstream

of the actual highly heating section are of aseptic design to eliminate the risk of reinfection, include aseptic packaging in packages protecting the product against light and atmospheric oxygen.

Ambient storage is normal.

- In the direct systems the product comes in direct contact with the heating medium, followed by flash cooling in a vacuum vessel and eventually further indirect cooling to packaging temperature.

The direct systems are divided into:

-- UHT Sterilizer: the process of heat treatment to reduce enzymatic activity and kill pathogenic bacteria. The main purpose of ygt pasteurization in dairy plants is to

make the product safe for use and to extend product shelf life.

-- Homogenizer: improves the texture, taste and viscosity of cream or milk-based drink and prevents sedimentation in the dairy products.-- Filling system: by aseptic filler to guarantee the clean air circulation and match aseptic package, to prolong the shelf time. with optional by Tetra pak box (200-1000ml),

PrePak bag (100-1000ml), Flexible BIB bag (2-220L).